The transformation of your digital image into a Tintype requires carefully tended equipment, unique software skills and a customised process that includes museum-grade negative printing and handcrafting application.

g

c

c

g

c

c

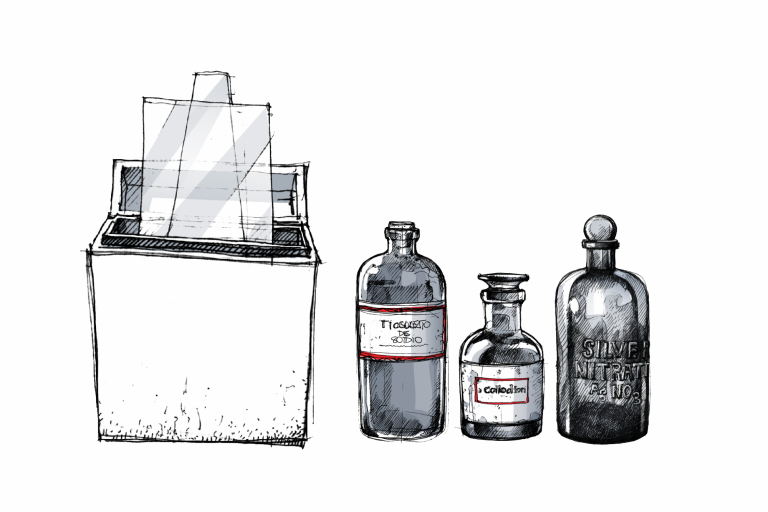

The transformation into a tintype takes place at our traditional laboratory through a process that uses a mixture of compounds consisting primarily of Silver Nitrate that we hand pour onto a thin sheet of black aluminium coated with a special emulsion (Collodion) mirroring the process from the XIX century.

g

c

c

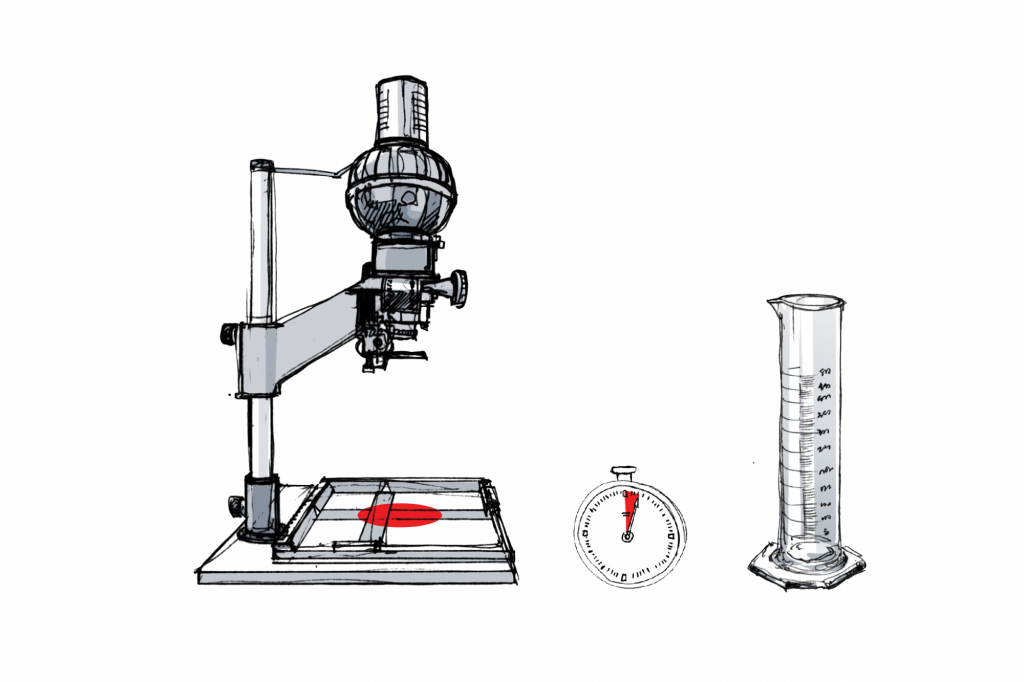

Once the thin sheet of black Aluminium has been coated and bathed in Silver Nitrate we exposed them using the transparent film to light, while still wet, under the photographic enlarger and develop them in the laboratory following the traditional steps. And, it is here where we see the magic of your final Tintype in our hands.

g

c

c

Your Tintype requires some drying and dusting after it has been developed. And to make sure that it doesn’t get damaged from oxidation we apply a varnish coat and follow the same drying method as the pioneers used. We want to make sure that your art stays protected and preserved for future generations.

g

c

c

Once your tintype has been varnished with museum-grade and sustainable materials we protect it with environmentally friendly materials, including an acid-free mat board that provides your tintype with extra protection and friendly UV plexiglass so that the tintypes are protected in direct sunlight.